EMS-7500 Core Measuring Tables are designed to facilitate your quality control processes for measuring the length, width and angles of your workpieces. It works in the measurement range of 7500 x 1500 mm. It is produced with two or three axis, servo motor axis control.

EMS-7500 Core Coordinate Measuring Table

EMS-7500 CORE COORDINATE MEASURING TABLE

The EMS-7500 Core Coordinate Measuring Table is designed to facilitate your quality control processes for measuring the length, width and angles of your workpieces.

EMS7500 Core Coordinate Measuring Table is used to measure and control the measurements of parts and surfaces, cross-section images, semi-automatically and manually.

It has high precision, safe, fast and non-contact measurement capability.

For ease of workpiece loading, the Table Table is produced at a 15-degree angle.

Core Coordinate Measurement Table Dimensions

It works in the measurement range of 5000 x 1000 mm.

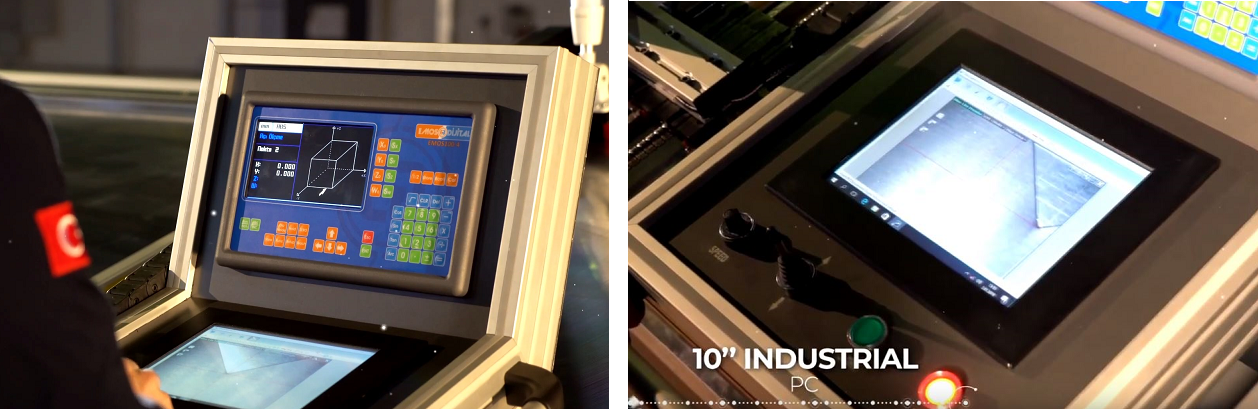

Our 10" Industrial PC and 7" Color LCD Digital Display work integrated with our special software.

You can make practical measurements with the 2D Workpiece Simulation Function.

There are 1000 pieces of fault compensation points.

You can achieve near-perfect accuracy with high-resolution, non-contact linear rulers.

It has a resolution of 0.001 mm (1μm) and 0.005 mm (5μm).

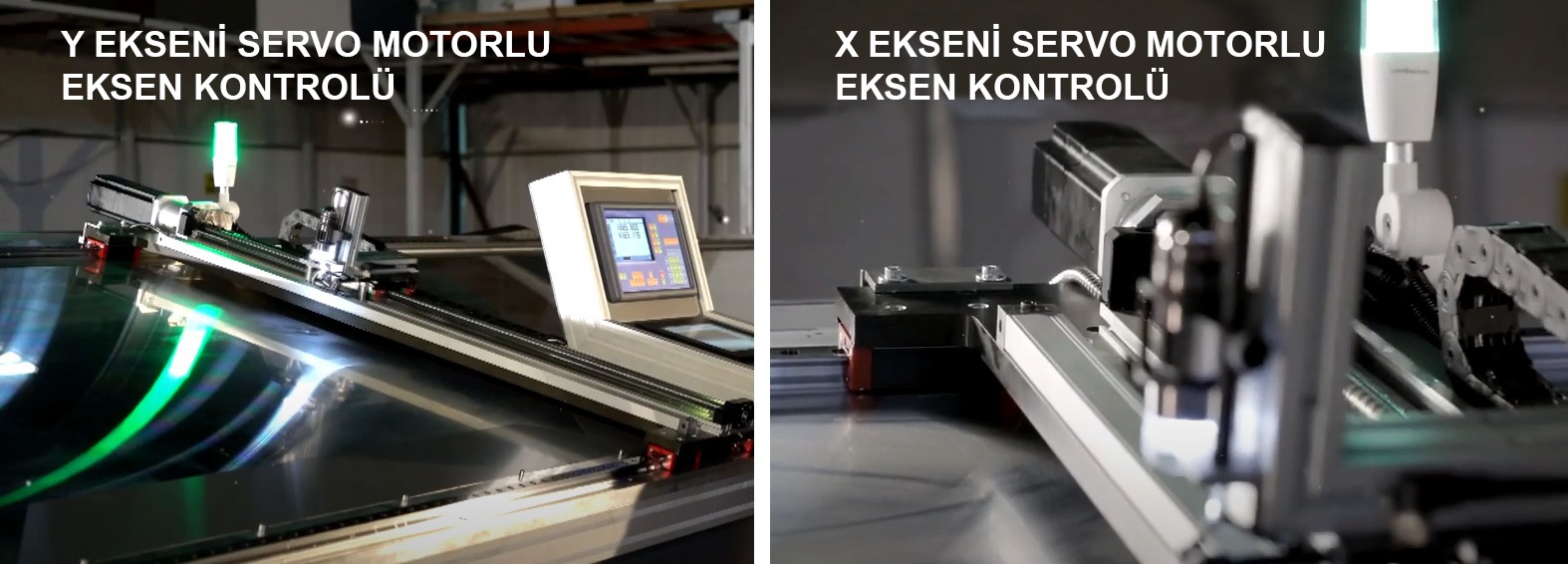

X and Y Axes are produced with servo motors.

Single or two axes work manually or semi-automatically.

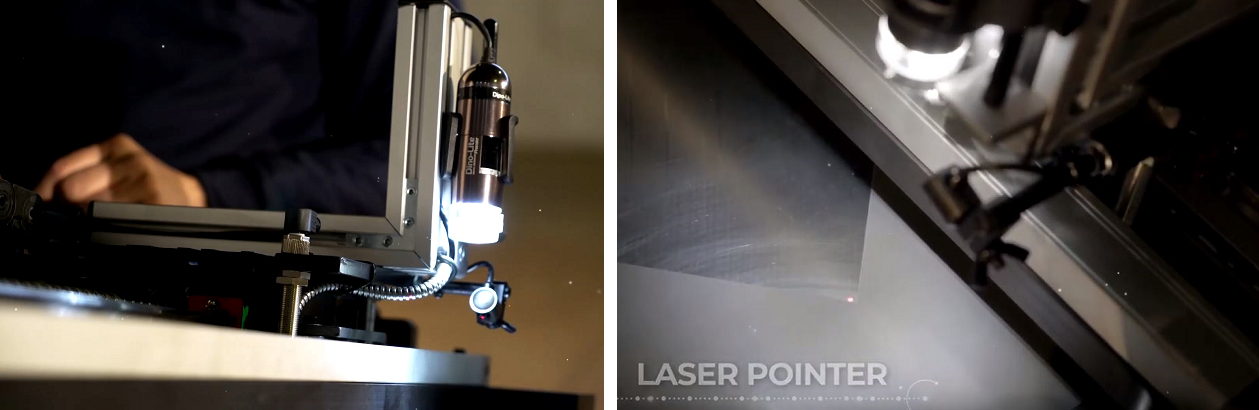

You can obtain non-contact measurements with a 5 Megapixel industrial camera.

It allows you to locate and take your measurements easily with the Laser Pointer without touching the workpiece.

Specially produced for Core Measurements.

We can produce in desired sizes and different versions.

| Resolution | 1µm, 5µm, |

| Body Material | Aluminum, |

| Digital Display | 7 Color LCD, Color Screen, Multifunctional Power: 220Vac, Aluminum Body, |

| X Axis Working Distance | 7500mm, |

| Y Axis Working Distance | 1500mm, |

| Plate-Tray Material | Ground Aluminum, |

| Plate-Table Thickness | 30mm, |

| Plate-Table Angle | 15°, |

| Linear Scale | Magnetic Encoder, Optical Scale, |

| Industrial PC | 10.1ʺ, |

| Y Axis Control | 0.4 Kw Servo Motor / Driver, |

| Y Axis Speed Control | 5 Kohm Infinite Turn Potentiometer, 2-Way Joystick, |

| Laser Type and Color | Dot-Red, |

| PLC | Analog Input PLC, |

| Laser Power | 1 mW – 5Vdc – 220 Vac, |

| Linear Guide Rail System | Schneeberger 25 mm - Linear Guideway: MRS 25 N, Roller Car: MRW 25 D G2 V3, |

| Software Language | The English, |

| Average Weight | 2250 Kg, |

| Machine Dimensions | Length 8500 mm - Width 2400 mm - Height 950 mm, |

| Accuracy | ±1.0%FS, |